When I set out to launch the Hygge Apps Monitor, I didn’t expect it’d take a year of relentless tinkering to bring my vision to life—an IoT product that blended calm and practicality. It started with digging out my old college breadboard to test Raspberry Pi and ESP32 chips, evaluating which could handle my idea. That kicked off a journey of refreshing my electrical engineering skills, navigating Federal Communications Commission (FCC) certification for selling electronics, and diving into 3D printing. What began as a spark turned into a full-on mission, ending with https://hyggeapps.com. Luckily the software portion of the product was smooth as I was able to model my SaaS design after a previous project created during Covid to host QR code restaurant menus on Google Cloud using Cloud Run and MongoDB Atlas.

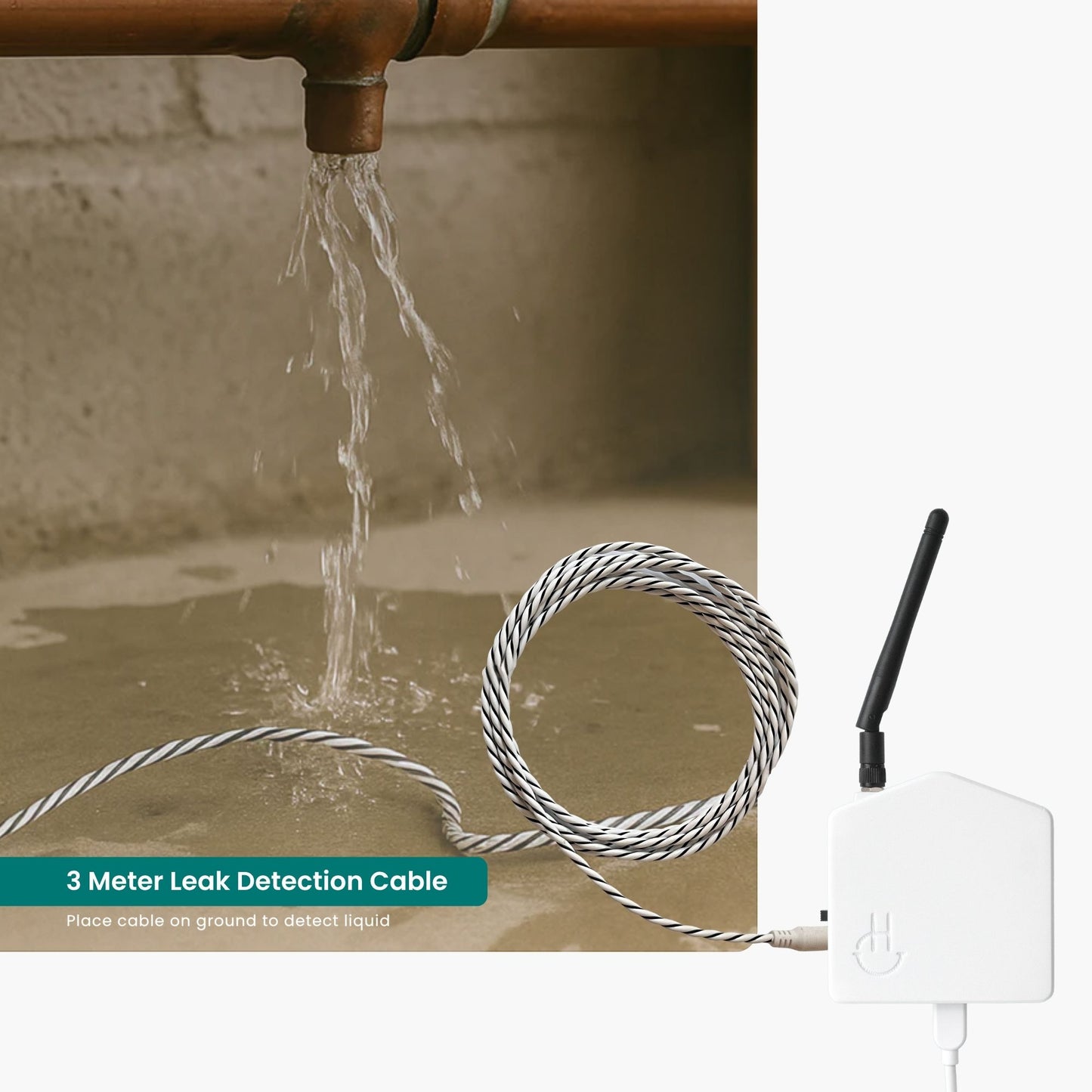

Prototyping was chaos and revelation rolled into one. I upgraded my lab setup after those early breadboard tests, experimenting with different temperature sensors, leak cables, and cellular modems. I even roped my dad into soldering early prototypes. Then came the 3D printing: I took lessons, got hooked, and bought a printer, churning out more designs than I could track. The FCC testing was another learning experience—with the final product version required to pass interference checks.

Some Early Designs

Batteries added another twist. Rechargeable ones tempted me, but the maze of certifications—UL, CE, and rigorous safety tests—felt like a wall. If rechargeable batteries were to be included they needed to be of the highest standard for safety reasons. This would add considerable cost to the project. After much thought I fell back on the principles of the problem I was trying to solve. The goal of the Hygge Monitor is to give you early warnings if a situation is starting to develop as water does not freeze instantly. Given most power outages only last a few hours, a battery capable of lasting 6+ days seemed reasonable for this model.

Hosting on Google Cloud’s Cloud Run was the final piece. Its scalability let me focus on the product, not server woes, tying the hardware and software together. Those late nights debugging sensors or reprinting parts paid off when I saw it all come together and got my first few customers. Looking back, launching https://hyggeapps.com was as much about rediscovery as invention. That year of breadboard experiments, sensor trials, and 3D printing marathons—plus my dad’s soldering assist—taught me to keep going. From the Boston flop to its year-long redemption, every stumble shaped the outcome. The lesson? Bringing ideas to life need patience, a good team (thanks, Dad), and a willingness to fail—then fix it.